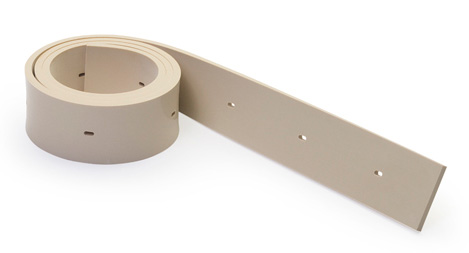

A man-made synthetic that is typically beige or tan, Gum Rubber squeegees offer maximum water collection on indoor floors that are smooth and even. Gum Rubber is not recommended for use in oily environments as it absorbs oil, which changes its structural integrity and dramatically reduces its effectiveness. Gum Rubber squeegees will wear faster than any of the other types of squeegee blades but are usually the least expensive.

Ideal environment: General purpose. Smooth, even floors with light traffic. Indoors.

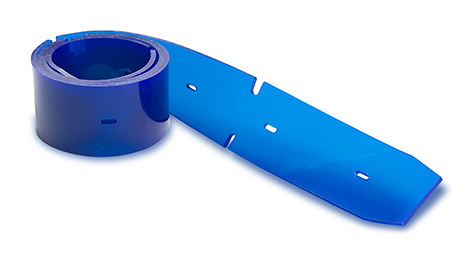

Engineered from Natural Rubber using advanced technology to perform as good as or better than Linatex®. Excellent tear resistance.

Ideal environment: Excellent results in many conditions, especially uneven and abrasive surfaces.

A man-made synthetic engineered to perform like Linard®. Excellent tear resistance. This is a harder material than Premium Red that helps reduce squeegee noise. Primarily specified for front squeegees.

Ideal environment: Excellent results in many conditions.

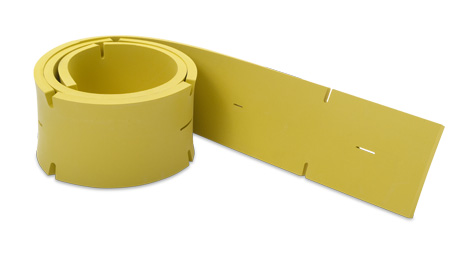

Uretek™ squeegees are engineered to perform as good as or better than OEM blades. They are extremely chemical-resistant and perform well in environments where oil or chemicals are present. Urethane squeegees are the best for use on rough surfaces and on old or uneven floors. They are typically the most expensive blades, but due to their excellent wear life, offer a great value.

Ideal environment: Applications that require oil and chemical resistance. Rough surfaces.

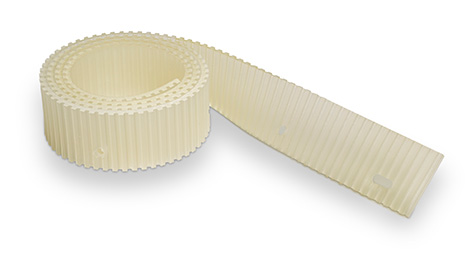

Ribbed Urethane squeegee blades are found on dual direction scrubbers and sometimes used as front blades on conventional machines. Cardinal Brush offers different colors to denote a different hardness that matches the OEM specification.

Neoprene was the first material introduced specifically for use in oily environments but has been replaced in many cases by Urethane. It is still a very cost-effective material for oil resistant applications.

Ideal environment: Applications that require oil and chemical resistance but where price is a factor.

| Squeegee Application Guide | |||

| Performance Traits | Tan Gum | PREMATEK™ | Uretek™ |

| Resilience | ▪ | ▪ | ▪ |

| Tear Strength | ▪ | ▪ | ▪ |

| Abrasion Resistance | ▪ | ▪ | ▪ |

| Wear Resistance | ▪ | ▪ | |

| Low Temperature Flexibility | ▪ | ▪ | |

| High Temperature Flexibility | ▪ | ▪ | |

| Ozone Resistance | |||

| Chemical Resistance | ▪ | ||

| Applications | Tan Gum | PREMATEK™ | Uretek™ |

| Oil Resistance | ▪ | ||

| General Purpose | ▪ | ▪ | ▪ |

| Hot Water | ▪ | ▪ | |

| Chemical | ▪ | ||

| Smooth Floor | ▪ | ▪ | ▪ |

| Uneven Floor | ▪ | ▪ | |

| Rough Surface | ▪ | ▪ | |